OMG. Work this week was insane and I don’t think it’s going to let up. Today I have some time to work on the build…So lets do this.

The proseal used on the bottom fuel line spacers took some time to set up but seems to be good now. I then used Dow 3145 RVT in the inside of the spacers to cushion the lines. Then installed the top halves of the spacers.

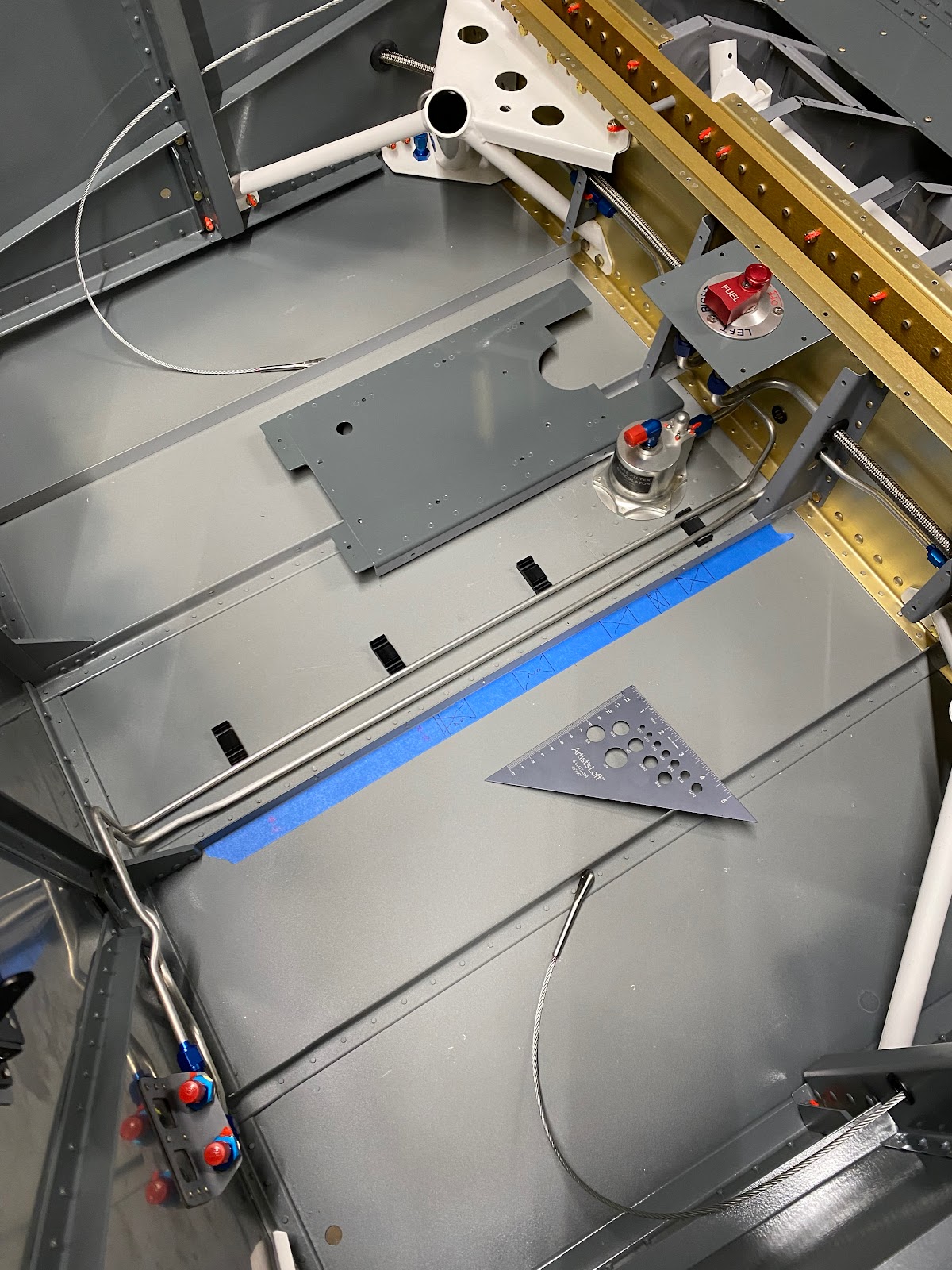

Next I installed the center tunnel cover and then the fuel pump. The fit is excellent.

The fuel pump cover was installed…looking good.

I really need to get the front instrument panel installed. This is something that I really have been dragging my heels on. On my initial fitting things the fit wasn’t great but admittedly I haven’t really spent much time on it.

First I need to concentrate on getting the F-7108A Forward Fuselage Rib installed and drilled to the firewall. This sounds much easier than it is. The holes in the rib and the bulkhead are not prepunched from the factory. This means a bit of head scratching and drawing many reference lines. I can go ahead and set the rivet holes in the Rib. I used the adjacent ribs as a guide for the top and bottom holes. Then used the fan spacer to set the remaining holes. (I used the drawings to drill a total of 6 holes in the rib)

Next I need to get the fitment of the F-7105A/B Sub-panel right. This area really doesn’t fit well as it currently sits. I noticed that the drawings show a line and when I’ve checked with other build logs, I see a bend on these pieces which I obviously not on the factory pieces. Sure enough….These pieces need to be bent

So, draw a line. Use a piece of oak and bend. Getting the right amount of angle takes some head scratching but I figured out. (Don’t ask the amount….I didn’t write it down). I drew up a guide in AutoCAD and printed it out. Bend made!

Now the fitment of the parts is so much better. Now its time to prep to drill the final holes from the center rib through to the firewall.