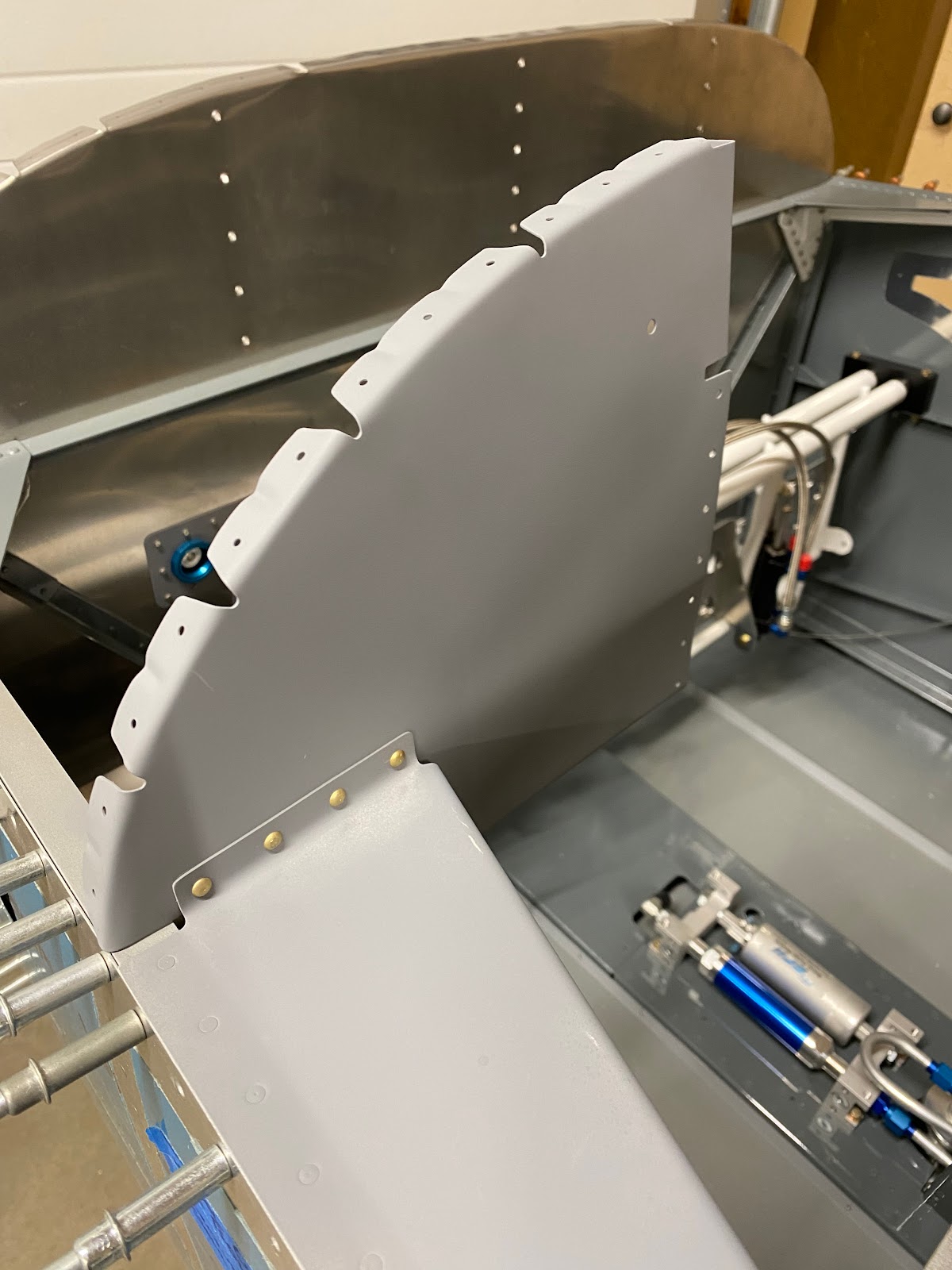

Next step to finish the riveting of the subpanels, was to install the six AN4704-4 rivets to the fuselage rib. Unfortunately the access in this area is horrible for both the pneumatic gun and for bucking bars. The angle of the fuselage side skin makes things poor for the gun, and the lip on the fuselage rib makes it difficult for the bucking bar. I ended up using the double offset rivet set and the results were disastrous.

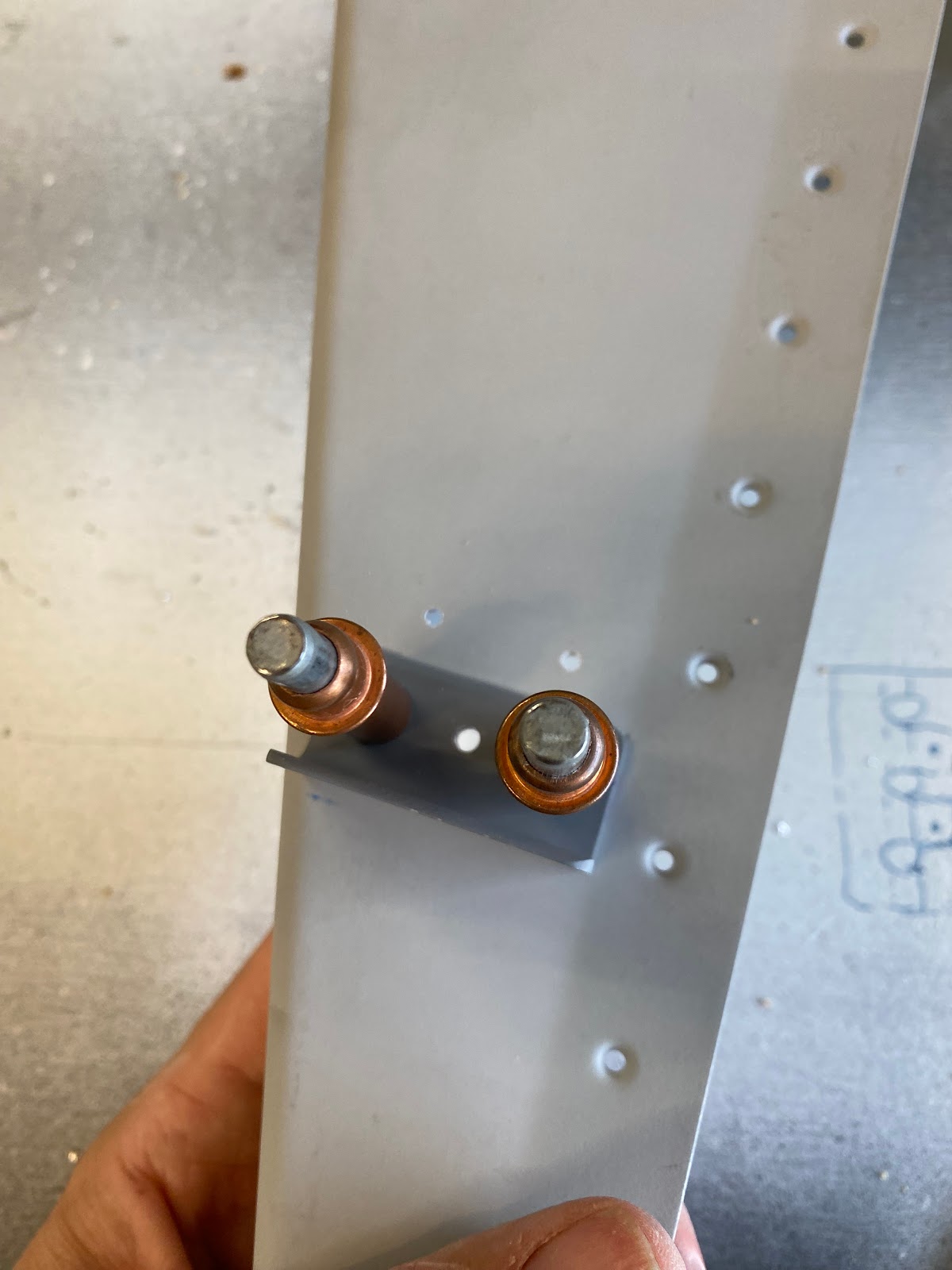

The first rivet was ok, but not great. The second was about the same. The third was terribly slumped. Not any good at all. I have to remove these! Standard rivets are just going to be awfully difficult to set correctly for me.

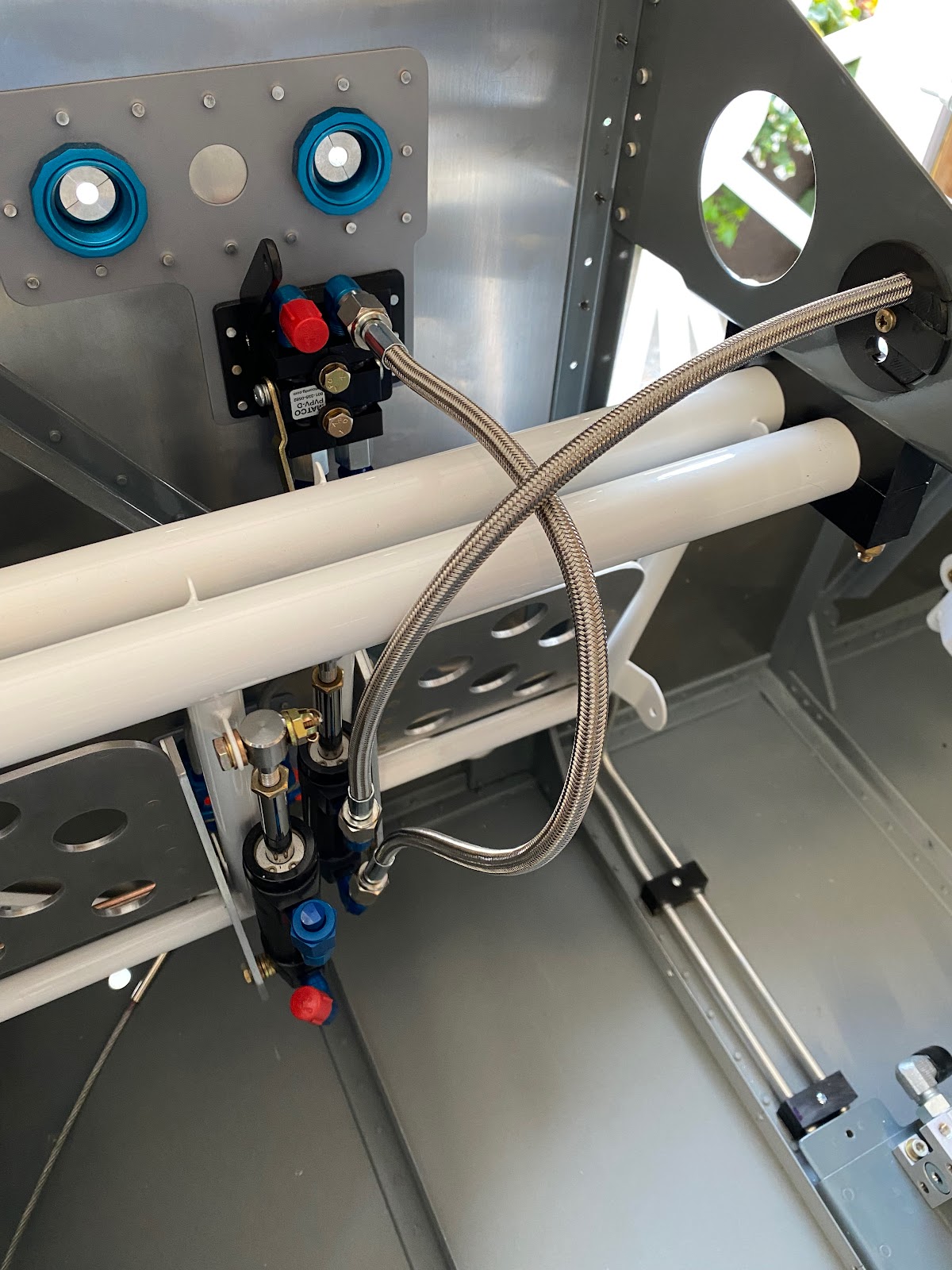

After inspection, the two top left holes are in good shape, the bottom left is not usable. The 3 on the right are perfect and untouched. Now, how to figure out an acceptable fix? There is no question that I will order a new F-7105B-L sub panel. After consulting with some knowledgeable friends, we decided that replacing the F-902-L fuselage bulkhead is not the most wise. The fix we settled on was to clean and salvage the fuse bulkhead. Install a new sub-panel and fabricate a 0.032" patch to fit behind. Essentially sandwich the fuse bulkhead between the patch and the new sub-panel. Of course I will abandon the idea of using solid rivets here due to the high risk of damaging the parts...again. I will have to use cherry max rivets here.

I used the dremmel and I deburred the holes with scotch brite. I used a round file on the large oblong hole to take out any sharp edges, as well I polished it with 800 grit sandpaper on the dremmel. I do not want any cracks forming from this spot.

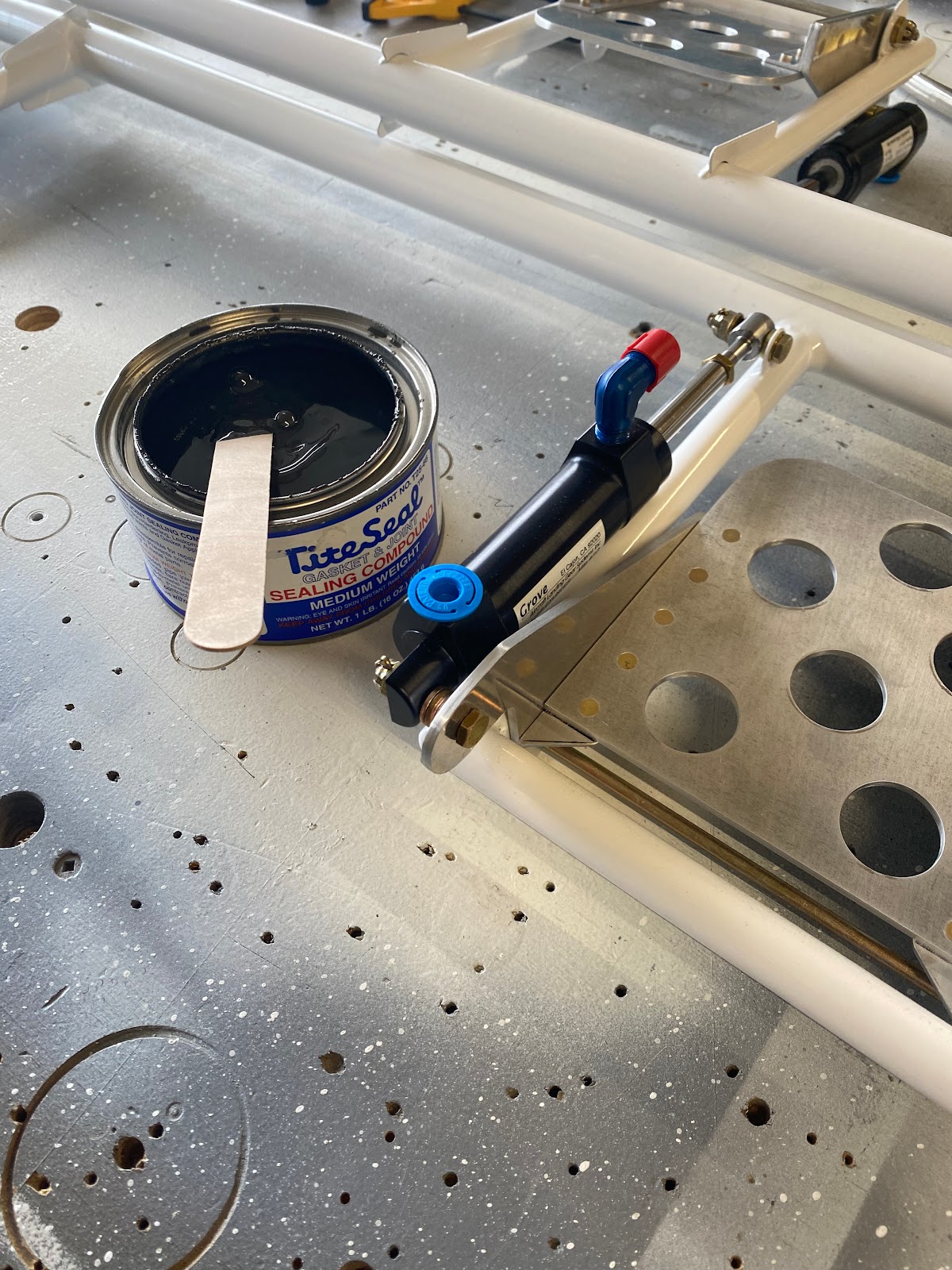

Next, I cleaned and prepped the areas to spot prime.