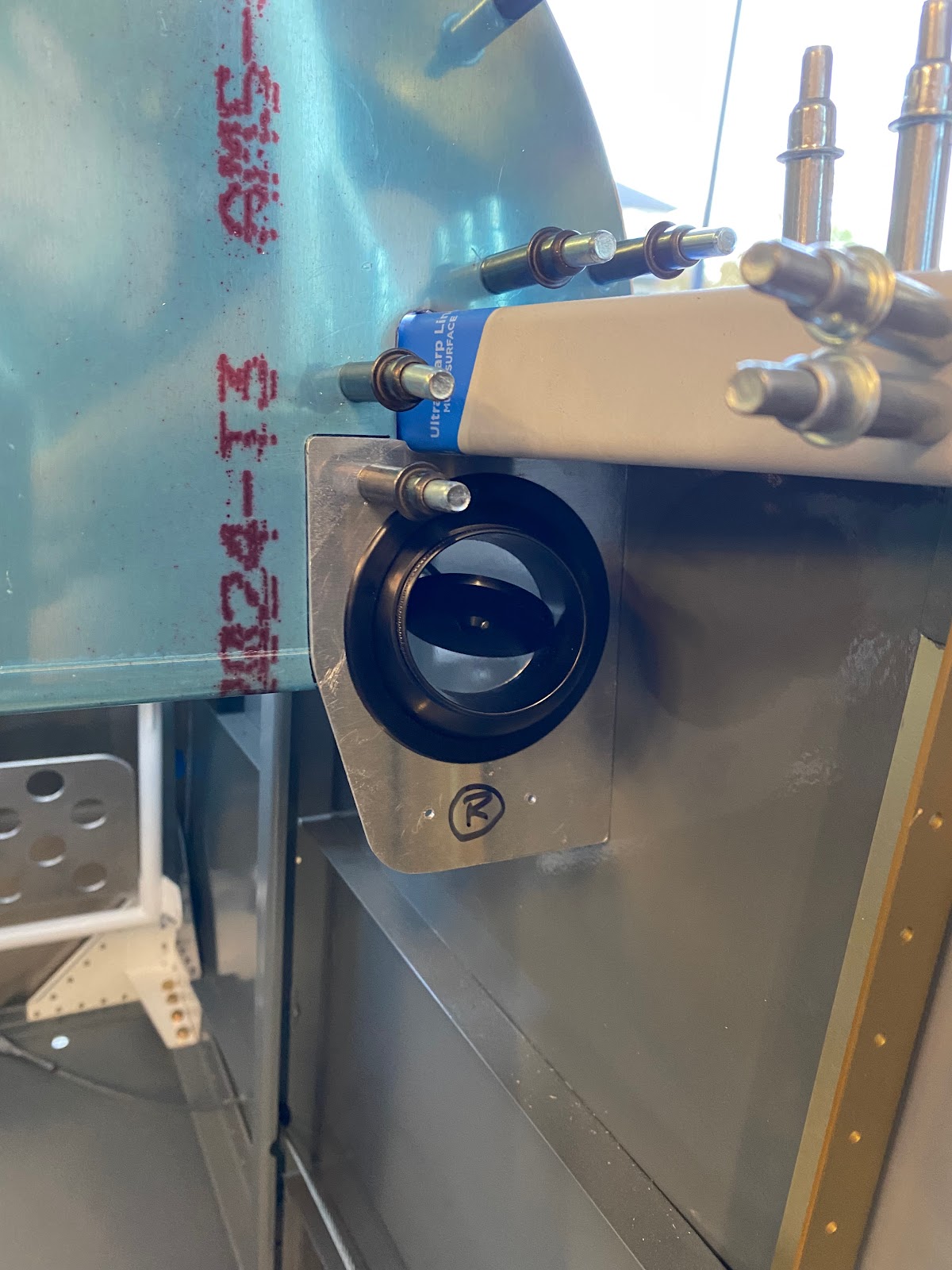

Today, I finished drilling the #8 screw mounting holes for the Vent mount plates in the F-793 brackets. Not much room here to drill, but my Nova tools 90deg drill comes in so handy. I am very happy with the fit and finish in the end.

During test fit of the vents I noticed there was a bit of a fit issue with the way the Stein Air vents secure with the F-793 brackets. there is a gap on one side of the vent assembly as the bracket causes some interference.

I thought first about trimming the mount bracket to clear the vent flange, but I think that is going to result in too much material being removed.In the end, I think the best and easiest option is to print a shim on the 3D printer, I can make a perfect plastic shim that will solve this. I will do that later in the build.

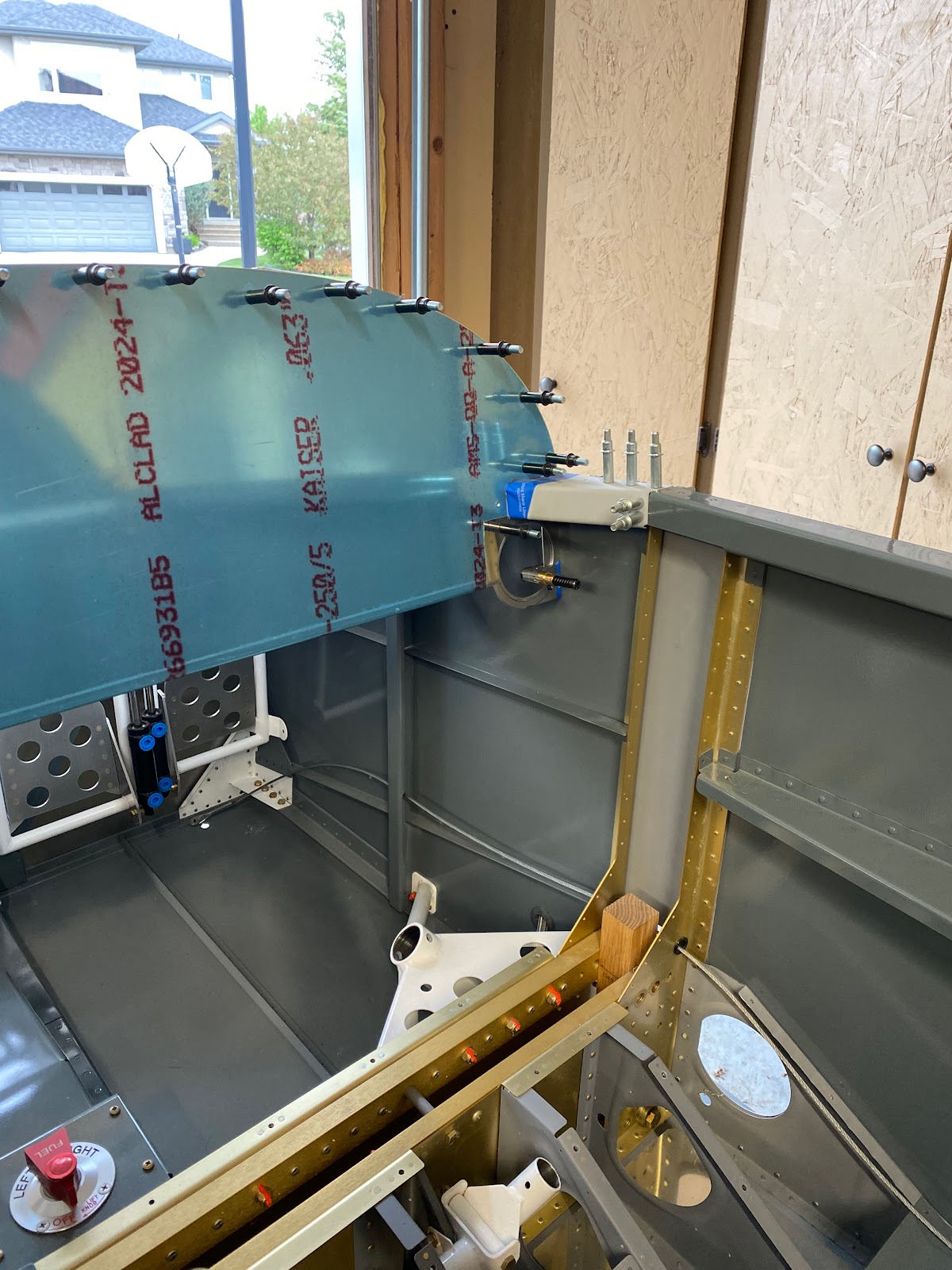

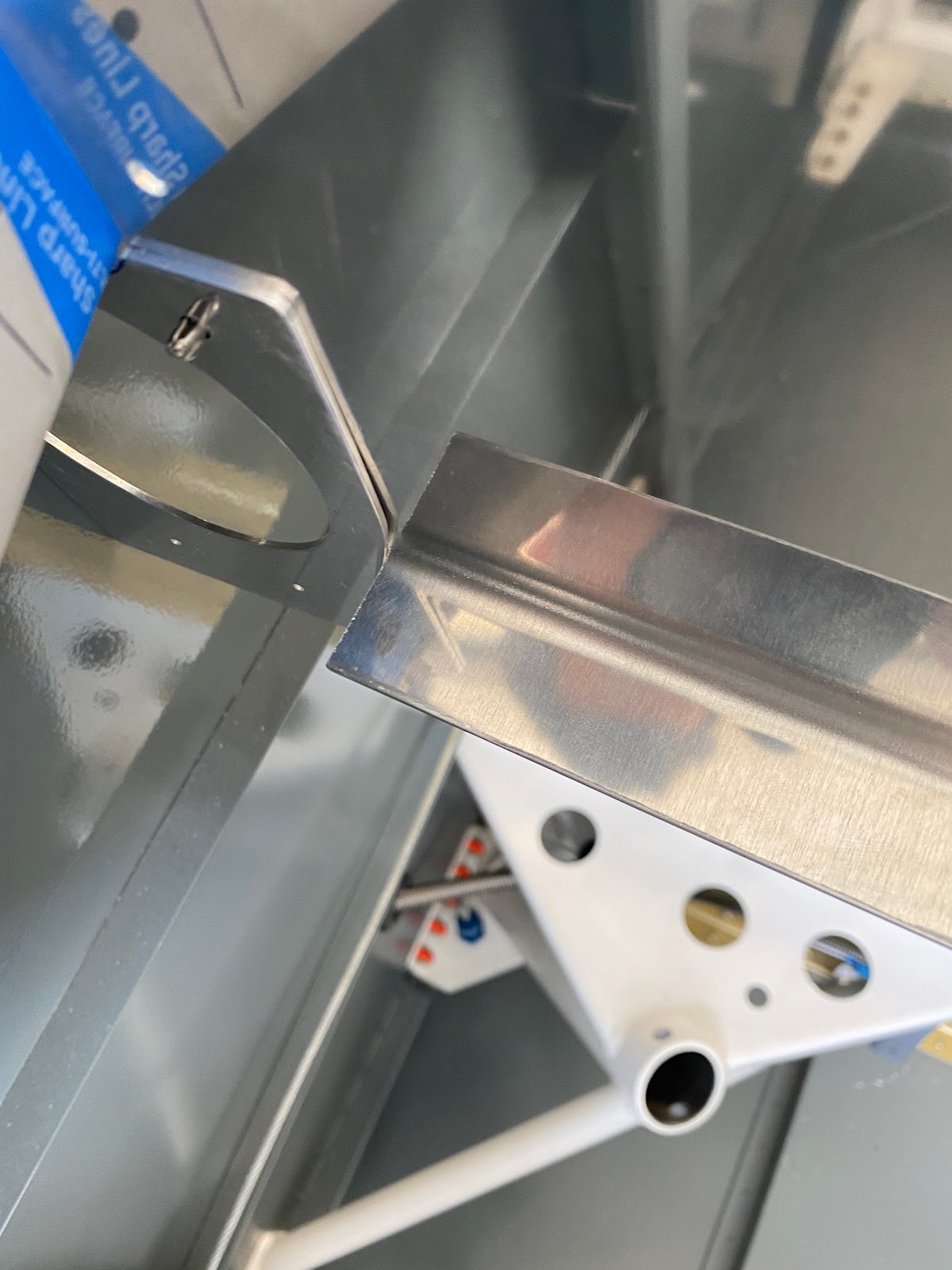

Next I moved onto fitting the F-746 fwd engine control bracket to the instrument sub-panel.