Using the paper template that I have test fitted, I cut the vent mounts out from scrap 0.063" aluminum sheet. Now comes the incredibly difficult and tricky part. I have purchased the standard SteinAir vents that are of similar size to the stock Van's vents. Well...they are actually a bit larger than stock. Drilling the very large 2 3/4" holes required for the vents is not easy. There are various tools that can be used....A fly cutter, a large diameter "wood" hole saw, but these are not precision tools. How do I know....well I wrecked a couple vent mounts. Good thing I have a lot of 0.063" scrap sheet (Thanks aircraft spruce).

The best scenario in my opinion in the absence of a proper one piece 2 3/4" metal cutting hole saw is to attempt to cut the hole using many drill holes, or a unibit. There is no question that this results in considerably more work as the hole has to be shaped using files...but the hole is fairly precise but best of all, incredibly clean.

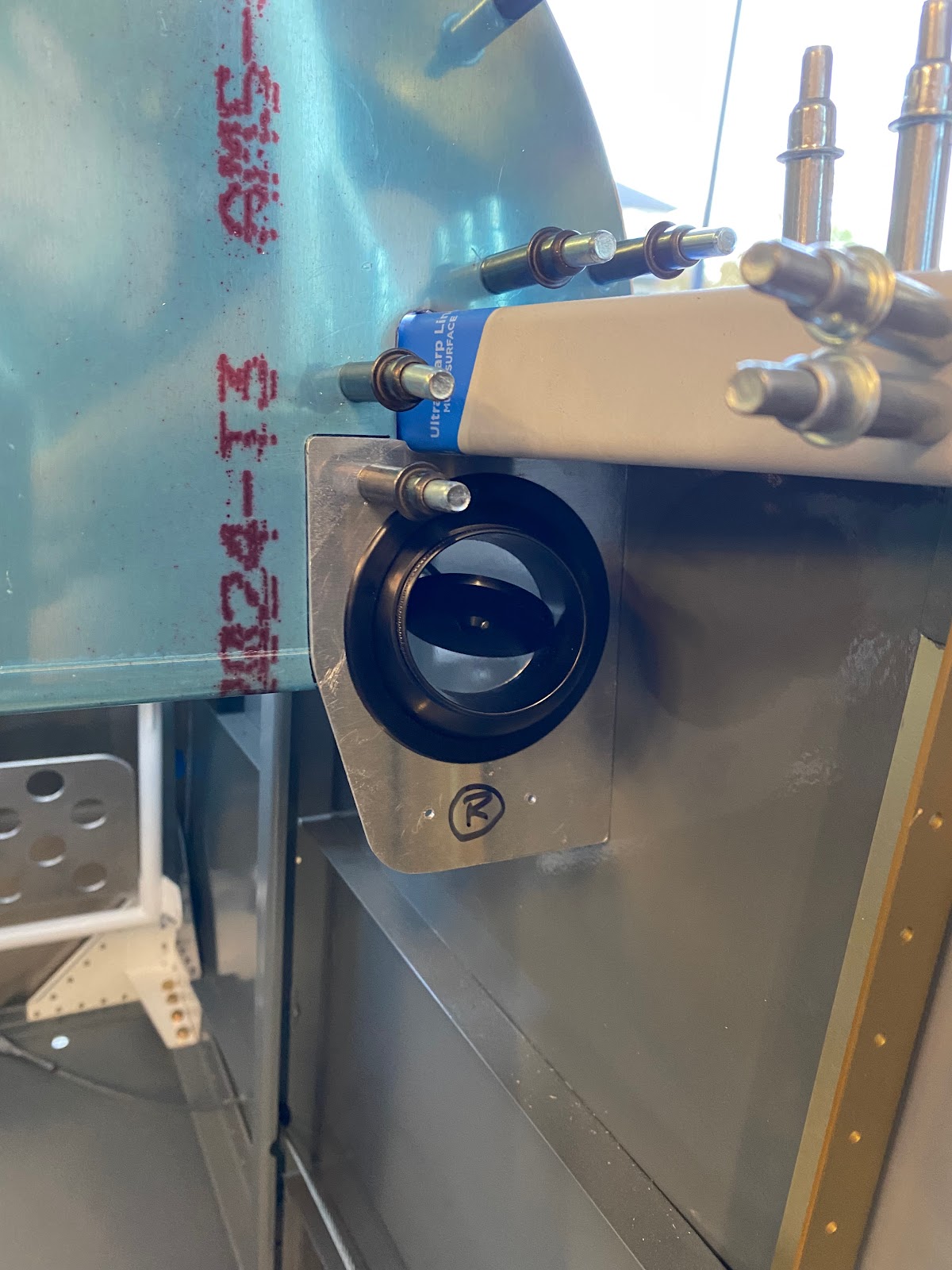

With both vent holes cut, I am now ready to begin fitting to the instrument panel. As you can see the vents interfere slightly with the instrument panel. I will need to trim a very small amount of material from the panel to allow the vents to sit flush.

The vents now sit perfectly within the vent mounts....Now I need to begin work on placing the mounts so they fit behind the instrument panel.