The placement of the mounting holes on the roll bar is fairly critical. You want to locate the forward AN3 bolt, and aft AN4 bolt as close to the longeron as possible without biting into the longeron material. There is also distances based on the existing canopy deck rivets.

It took me a little time to figure how best I was going to get this work done accurately. Ultimately I thought is best to 1 - Drawing out all the positioning on AutoCad. Then 2 - Use the AutoCad design to make a drilling template.

With the template made and #40 pilot holes drilled, I compared that with the Autocad template and found everything appears to be good.

Now its time to clamp the drilling template to the actual canopy deck. You will note how I made a #30 reference hole on the most forward part of the Template. This allows me to locate that hole directly above the center of the required rivet on canopy deck.

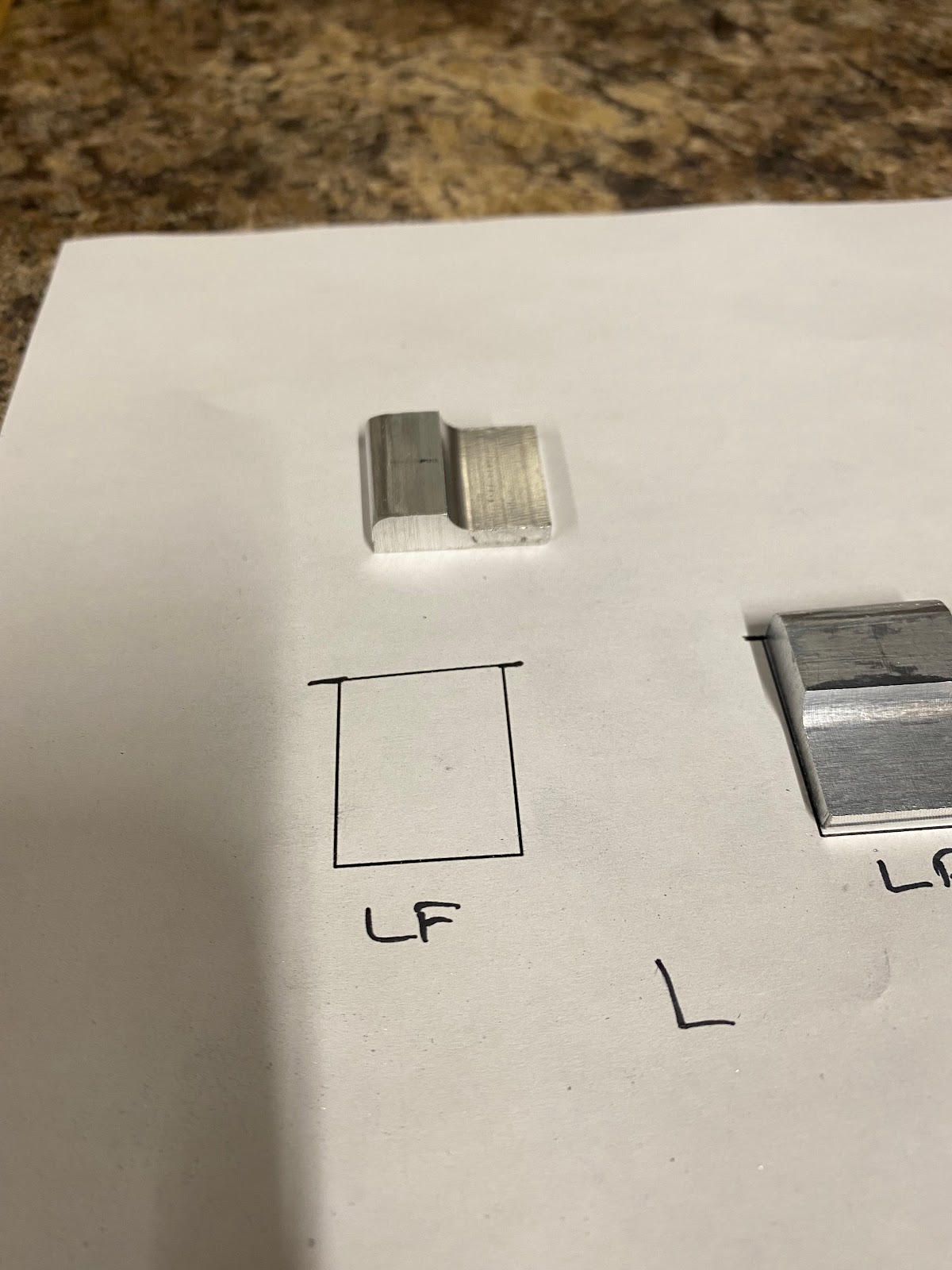

Now, After careful positioning and checking. I drilled the two pilot holes for the mounting bolts to #40. Before I go too far I want to ensure that the holes are in the correct location. I have the ability to "Walk" the pilot hole over if needed. Prior to drilling, there is not an easy way to check this. Once the pilot holes are drilled I can then access the underside and see exactly where we are.To do this...I made two center guides that I can slip underneath the canopy deck and see with easy how centered the pilot hole is.

We are in really good shape! I am very happy with the location of these holes. Now I need to begin fitting the mounting spacers. These are a bit of a pain as they need quite an amount of work to fit properly. To make things more difficult, accessibility for the trial fit is terrible. Before any pilot holes are made. We need to make sure the spacers are cut down and that the inside edge has a fillet for proper nesting in the canopy deck.