It’s been quite some time since I have worked on the Plane. Our lease on the office was coming up for renewal at the end of September and given the declining state of the downtown core, as well as the declining state of our office building the writing was on the wall for our need to move to a new office.

So…I’ve been hard at work searching for new office space, and then designing all of the architectural and electrical for the new space. The designing, drafting and attending to the new construction has taken a considerable amount of time and I’ve not been able to spend any time on the plane. Add to that we need to move the office and get it all set up and running has been quite an amount of work as well.

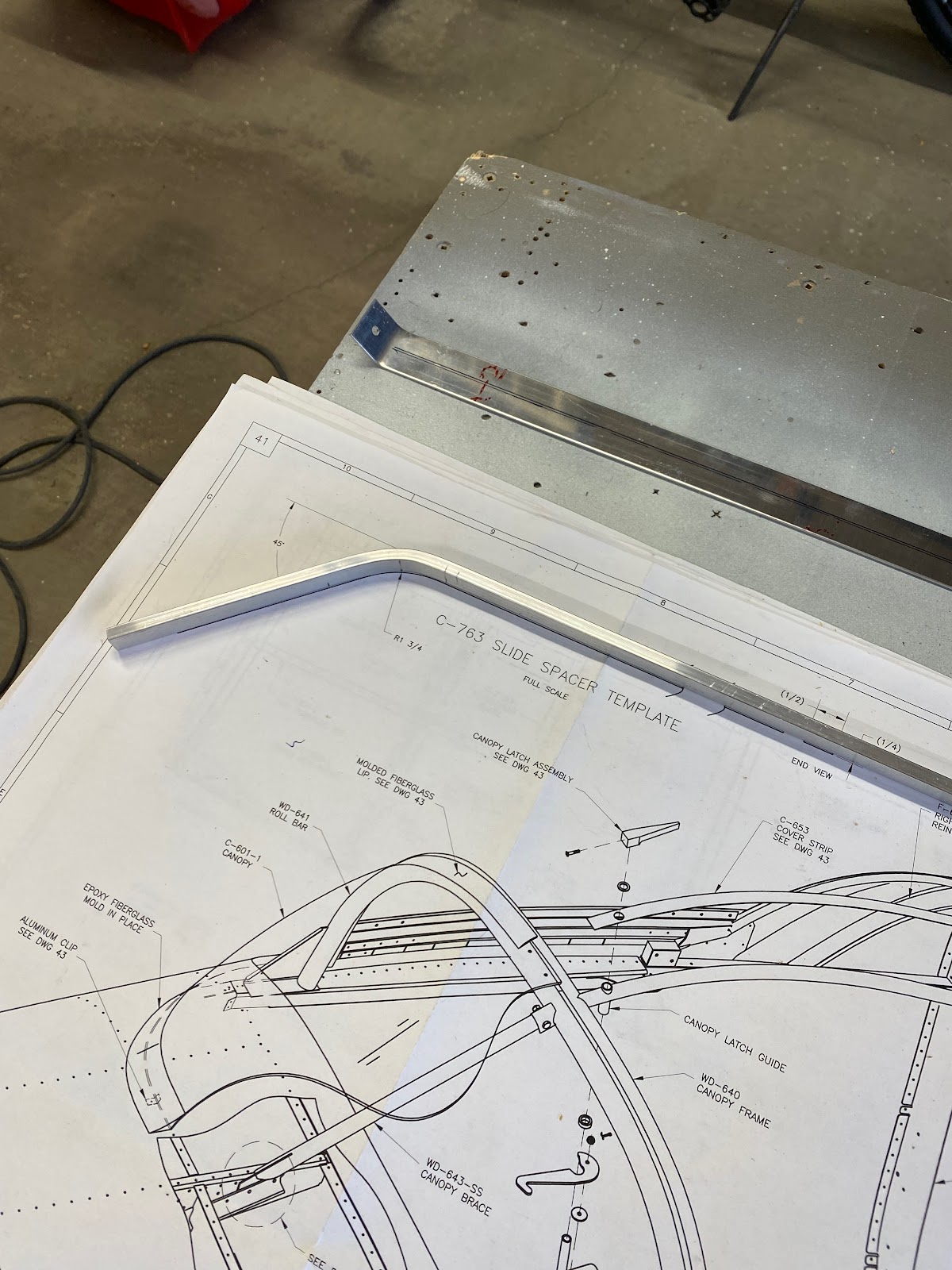

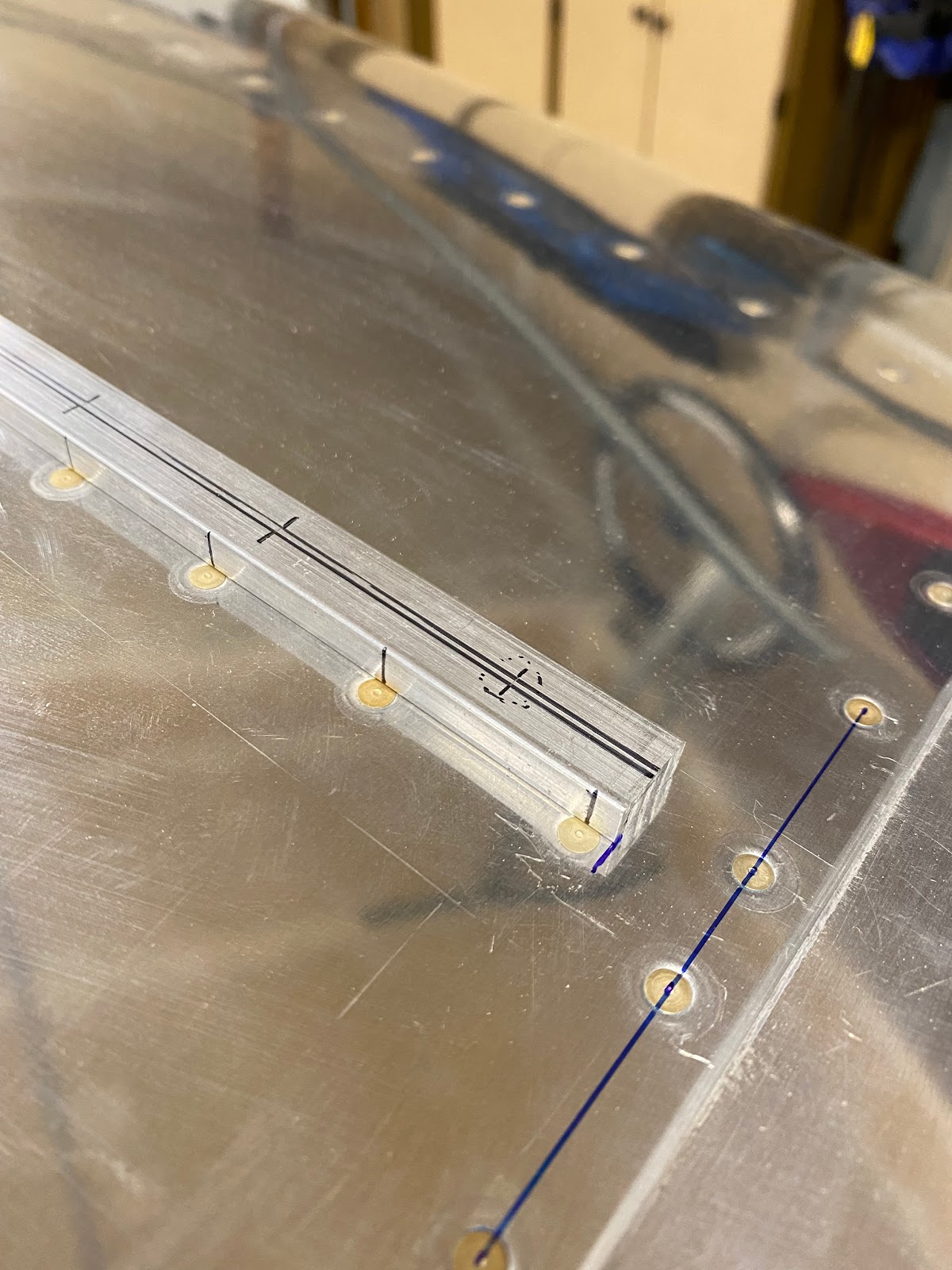

That said…Hard work has paid off in dividends because I think our new offices are fantastic. I will get back into the swing of things with the plane now with the Christmas break. Lots to do to finish the cockpit panel off and then I can dive into the canopy.