I've basically finished the items noted in the instructions up to the point where it says "Riveting the forward side skins". The instructions note that " There is a laundry list of small task that must be completed. You may have done some already. If not, complete them now" The instructions are rather vague on what these might be. But I've already started a to-do list some time ago on all the things I need to still finish off.

Here is my laundry list of items (in no particular order):

With everything still cleco'd together

- Finish match drilling the fuse (center section/aft section. seat ribs, etc, etc)

- Open up the #30 holes to 3/16" for the front wing attach bracket.

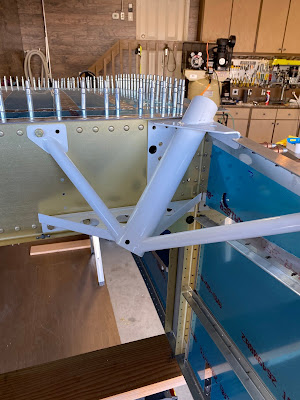

- Drill landing gear weldments to the side fuselage.

- Open fuel vent hole in side skin/gear web to 1".

- Open brake line holes in bottom skin to 5/8" (Align with gear weldment).

- Open fuel vent holes in bottom skin to 7/16"

With everything taken apart

- Drill the 5/8" rudder cable holes in the F-902 and F-724 bulkheads.

- Drill the static line holes in the F-724 bulkhead.

- Finish strengthening and drilling the armrests.

- Finish rough-in of the side steps (I'm contemplating on when to do this...now, or when I flip the fuselage....I hate working upside down).

- Finish installing the 6 rivets in the firewall.

- Complete the edge roll to the bottom skins/side skins.

- Finish drilling the holes attaching the tabs of F-724 and F902 bulkheads to the longerons.

- Prep the baggage are panels, etc for nutplates (All panels are removeable).

- Debur, edge prep, countersink etc.

- Prime

- Install the nutplates as called for in the plans and also for the baggage area removable panels.

Well....time to dive into it.

The first item of business I dove into was to finish match drilling everything. I started at the center of the seat ribs and worked outwards.

There is just a ton of cleco's

Next, I decided to tackle strengthening the arm rests. Yes, it wasn't on my primary to do list, but I think it will be a fun one to do. Material selection was a tough choice. Lots of opinions out there. I want good strength but not with too much a weight penalty. I opted to use 3/4"x3/4"x1/8" thick angle. About the heaviest material out there! Ha Ha. But I do intend to try to cut it down and drill lightening holes to help with the weight. So the angle to start with weights just over 200 grams each side.

Now I clamped the angle to the work table and used a router with a small radius round over bit to put a radius on the vertex of the angle. Does the aluminum dull the router bit....Yeah probably. Does it do an awesome job, heck yeah!.

With the edge finished, the part nests nicely into armrest. Weight is now reduced to 195 grams. Next, I want to trim the flange of the angle that sits proud of the armrest.This takes a bit of time and work to get trimmed and smooth, but the result is fantastic.

Weight now drops to 173 grams

I used the fan spacer and drilled the angles to the arm rests.