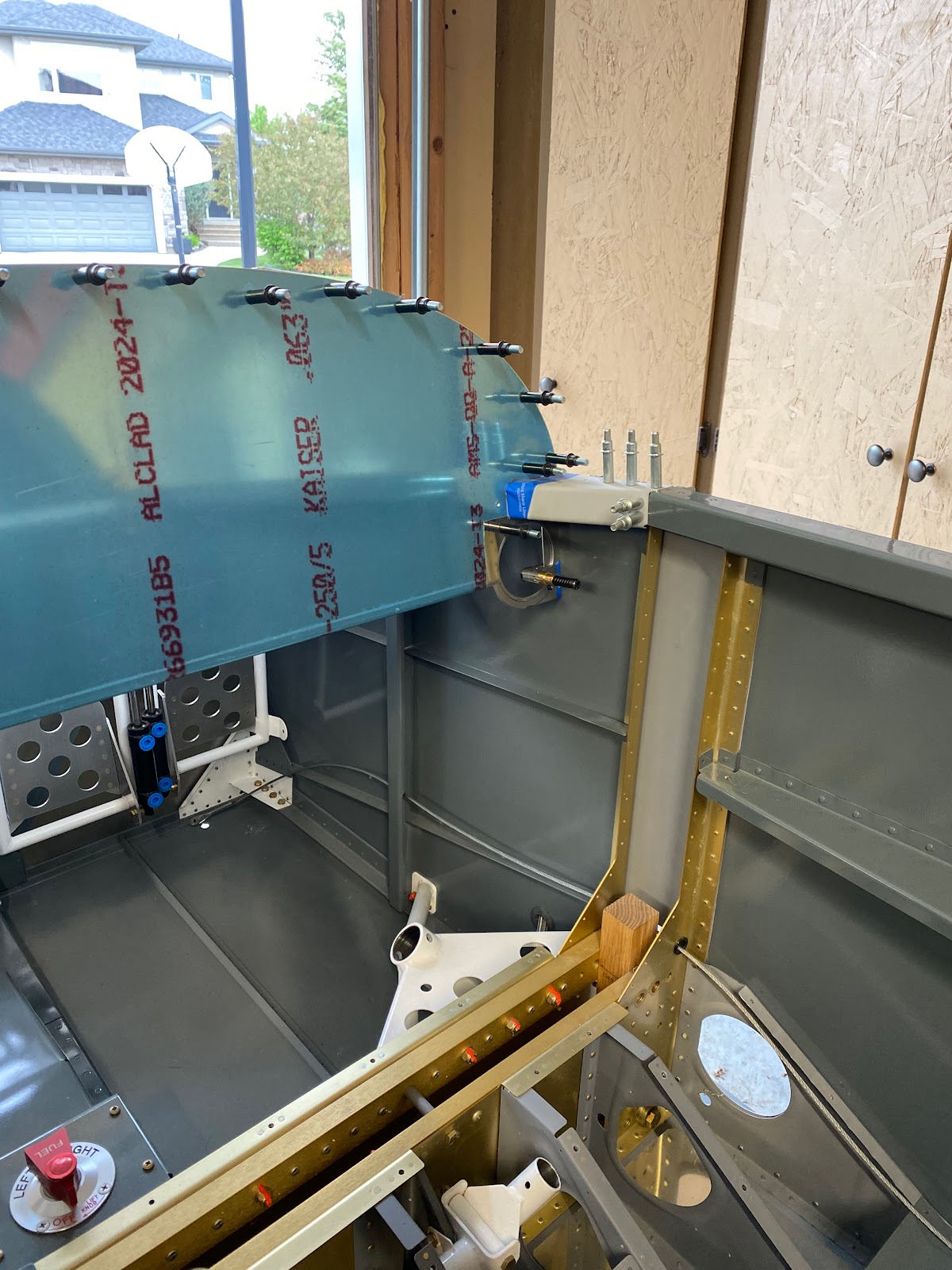

If fitting the roll bar to the fuselage doesn't make you scratch your head, trying to bolt the roll bar (tightening the nuts) will.

On my first attempt and fitting the canopy frame I can see that I have so work to do ensuring that the roll bar is 90deg to the longerons. I have a gap between the roll bar and the frame.

Making things more tricky is that I only have access to the AN3 bolts/nus of the roll bar. I can slip AN4 bolts into the rear mount of the roll bar, but due to the canopy deck lip accessibility to get washers and nuts on is near impossible. I need to get all bolts on and tightened if I have a hope of getting the roll bar positioned properly. I spent a few hours investigating my options, looking at special tools on the net (injector wrenches, offset sockets, etc) anything that would hold a nut in such a tight/odd space. Nothing I found would work. I see some folks on Vans Airforce forums just put a large scallop on the underside of the lip of the canopy deck allowing them to use a normal socket....This was my original plan, and went as far as drilling pilot holes in the lip. But I just couldn't bring myself to cut up so much of the lip. Between damaging the final paint and messing with the strength of the part, it was not the option I wanted.

After some lunch, and a strong coffee, I had an ah-ha moment....Couldn't I just print a socket tool? I don't know why it took so long to think of this, but it could work. Assuming the plastic is strong enough? Well, I am currently using PLA+ in the printer. PLA+ is more rigid than regular PLA and its tensile strength is about double....give or take. I'll give it a shot and see.

I started to create a socket shape to accept the AN4 nut.

Next, I created a shape to test if I can get it to fit up under the canopy deck lip.

Once I had all the rough dimensions worked out, I furthered the design to allow the tool to not only hold the nut, but the washer as well. Even when so far as filleted all the tool edges and cleaned it up!