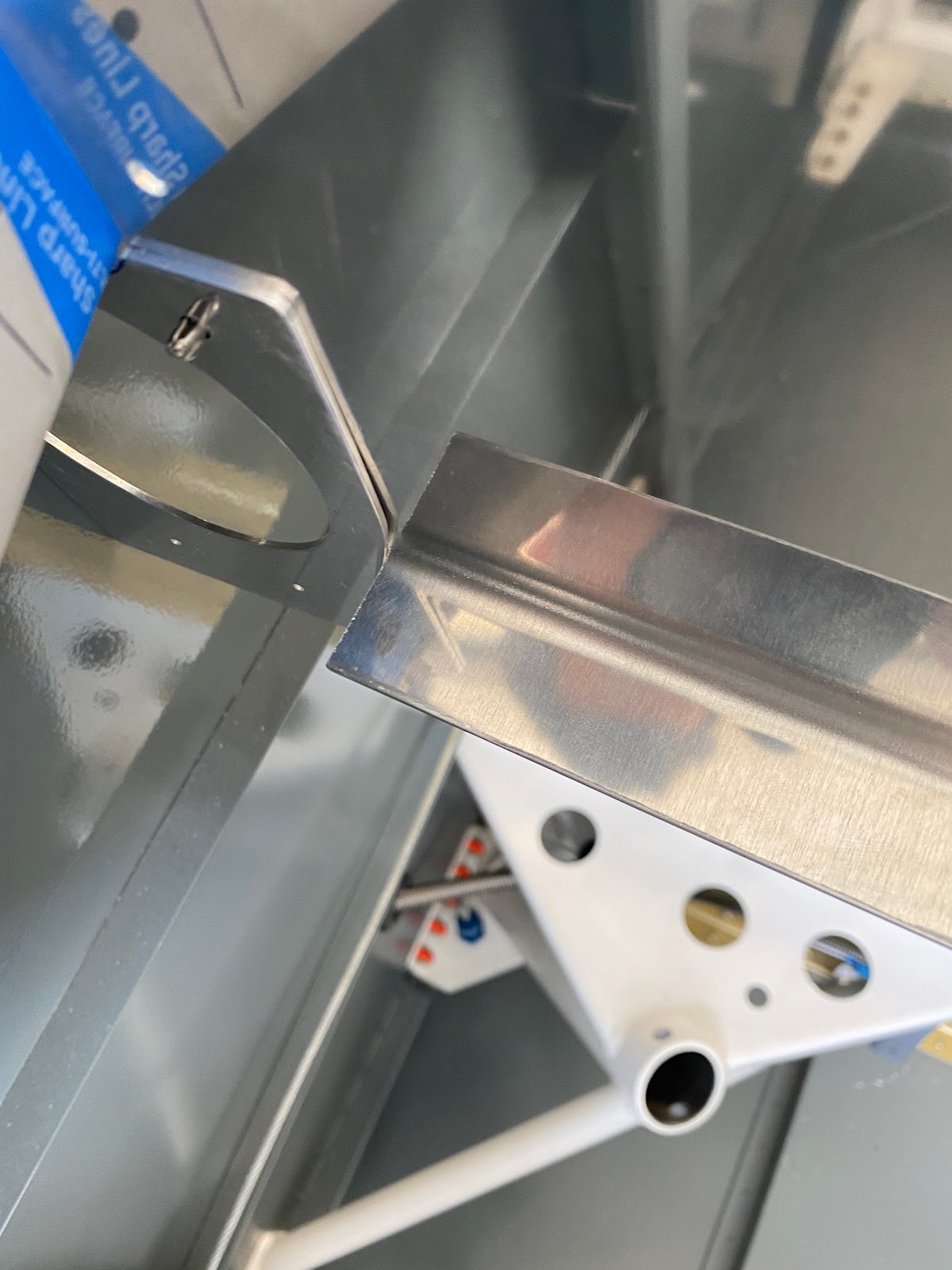

Before I start mounting things, I need to fabricate a control horn that I can mount to the WD-613-EF flap weldment. There's no real dimensions to work from, but from my initial prototypes, getting the control horn mount point closest to the center of the pivot point of the weldment is needed. So I made site the control horn was asymmetric.

Next I marked lines on the flap position sensor to note the maximum and minimum travel limits of the sensor.

I temporary clamped the assembly to the backrest brace and then used a 12V battery to raise and lower the flaps. Eventually I was able to dial in a sensor position and rod linkage length that would allow the flaps to travel to reach both min/max limits on the sensor.

I completed the final fitting of the control rod linkages, marked the sensor mount positions and drilled for #6 screws and bolted the assembly to the back brace. Everything works perfect!