Well...what can I say! I really messed up again! When I got home from work today I set off to finish toolbox #2. When I went to rivet the 4th (and last rivet) to attach the handle to the lid, the rivet gun slipped off the head and bent to toolbox cover!!!! AHHHHHH!!!Lesson learned! Do not have you wife hold the lid and you try to rivet. It's just not a good way to work.

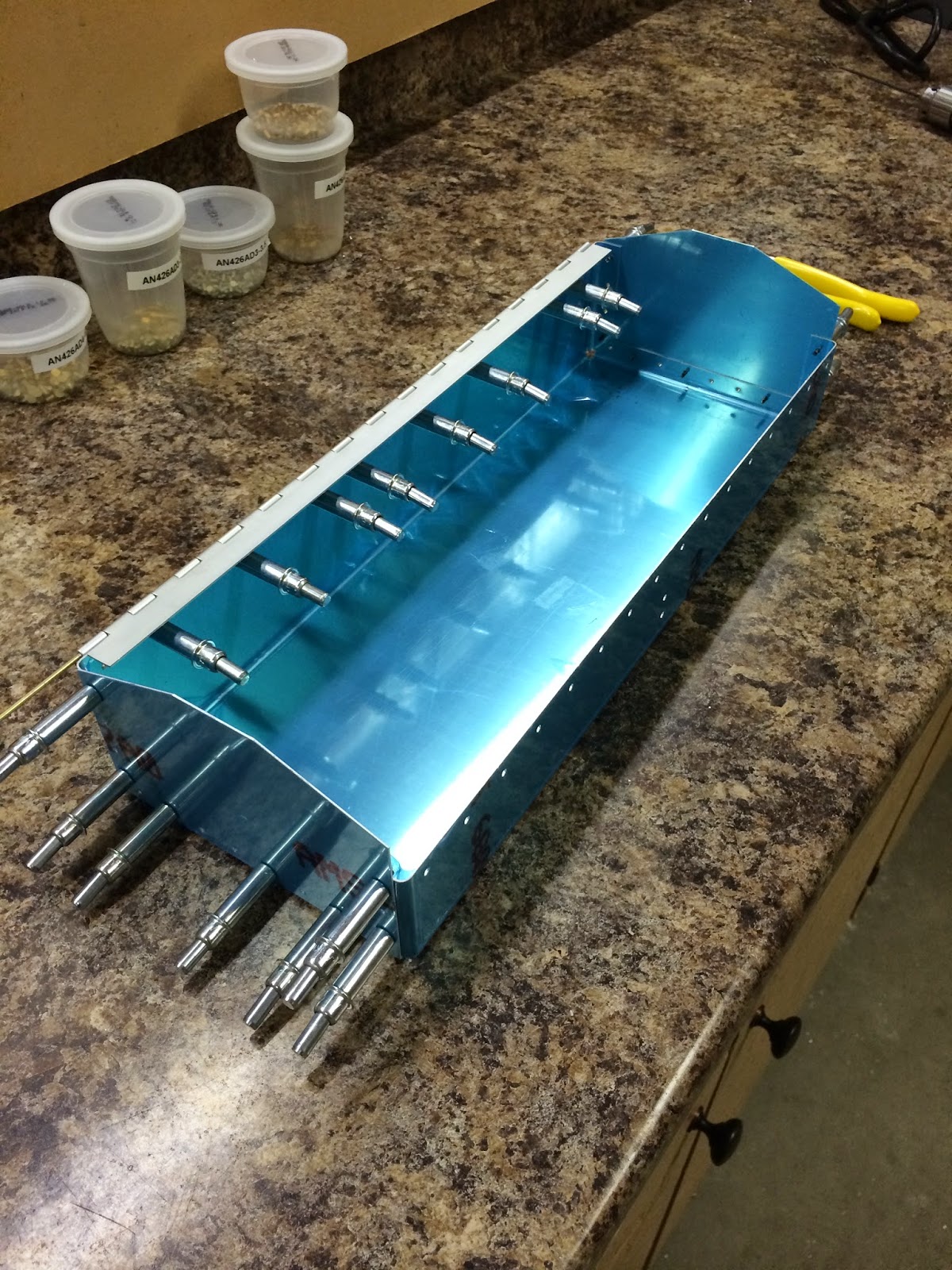

Lucky for me, I had a third tool box. In no time at all I was back up to speed. This time around I clamped the lid in the vice and bucked the 4 rivets for the handle. I countersunk the bottom hinge and dimpled the top hinge. After that everything was moving like a Swiss Watch! Precision and Perfection!!

Wednesday, September 17, 2014

Tuesday, September 16, 2014

Toolbox #2

I ended up ordering two more tool boxes and practice

projects from Vans on the weekend and they arrived today! Wow that's quick! I

wanted to do another tool box and I really wanted to practice more setting

rivets. I also wanted materials so that when I start the empennage, I can get

some practice in again before I buck rivets on the real piece. Have the new

tool box #2 almost done. I'm really pleased with it. I have countersunk the hinge

instead of dimpling it with much better results. However I find it difficult to

countersink the hinge when a dimpled aluminum sheet is placed overtop. I need

to countersink a bit deeper but it's very difficult to get it right. I also

find it difficult to countersink when the loops of the hinge are sticking up as

it interferes with the countersink cage. I will have to find a better way to do

this come build time.

Monday, September 15, 2014

The DRDT-2!

The DRDT-2 dimpler has arrived. Trip helped me set it up and

I messed up the #6 screw dies. I bent the retention spring on the die shaft and cant get it bent back. Darn!

Sunday, September 14, 2014

Still learning

Learning lessons today. Spent some time on the practice project. All in

all it turned out well. But not as good as it needs to be. I

counter-sunk the number #30 holes in the aluminium angle. They were

perfect if I used the 426AD4-4 rivets, but when I put the 0.040 dimpled

skin over top the angle... Skin does not sit flush on the angle because

the angle countersink was not deep enough. Makes perfect sense now that I

think about it, but I realized it after I riveted. I also played with

the air settings on the gun and found that lower settings work so much

better that the higher settings I was using. I also discovered why the

flush rivets do not sit quite so flush with the skin. My swivel flush

set has a rubber ring around it which sits proud of the skin. Unless I

press really hard with the gun, there is a possibility that the rivet is

driven with its head slightly proud of the skin. I also noticed that I

scratched the head of my flush set so now each flush rivet is being

marred. After reading up on the forums, I see that you can polish the

flush rivet set (one the rubber is removed). Did that and it turned out

very nice!

Saturday, September 13, 2014

Finish the Toobox and start the Practice Project - 5.0hrs

I woke up this morning and could wait to finish off the tool

box. It's really bugging me that the riveting did not turn out as nice as I

wanted it to. I used the pneumatic squeezer on the front stiffener which turned

out very nice. I think if anything I now feel quite comfortable with the squeezer.

I tried to buck a few rivets and i'm a little more pleased with the results. I

need more practice to set up the rivet gun pressure and get the feel of the

trigger. I also need to practice holding the bucking bar more. I know one

thing. I like the tungsten bar WAY more than the steel bars. I finished off the

toolbox with less than desirable results. When I riveted the handle on I

slipped with the gun and dented the top...doohhh!

I took a break for a while and then I went and dove into the

practice project. Everything went really well until I went to drill the

trailing edge. the holes in the two skins do not match up really well. I made

the best of a bad situation and when I was done, I was happy with the job....Until

I cleco'd the structure together and saw how crooked the trailing edge was. I've

seen folks complain about this on their blogs however I see just how critical

it is to lay everything out on a smooth hard edge, and go slow. Ensure that

each hole is drilled precise! I'm stopping for the day! I really need to practice

a lot more. I feel like i'm rushing through things way too quickly and I am

making mistakes. I want to order another tool box and practice project. I

really want to nail this before I start on the plane.

Friday, September 12, 2014

Tools Arrive & Toolbox construction begins - 7.0hrs

The tools came to the door!!! Yeah! Took inventory and laid everything out. Planetools.com has a very nice kit and I was really pleased with every piece. Everything came out of the plastic and had a good wipe to get the tool oil off. I didn't waste any time. I started the toolbox project and everything was falling nicely into place. The clecos when on, the holes where lining up. The plans were a bit difficult to follow and I choose to assemble the pieces in a bit different order. By the end, I had a perfect tool box! I was feeling really confident. Then I began to rivet.....this is where everything went south. I tried the pneumatic squeezer first, things went much better when i found that i could tease the trigger and close the gap to make sure that the squeezer was on the rivets square. But then I pulled out the rivet gun....and made a real mess of the toolbox. I found it difficult to hold the gun against the work, while holding the bucking bar. then when I pull the trigger everything seemed to jump all over the place. I had to drill out about 5 or 6 rivets, a lot of rivets were not nice and square. I can see that I am going to need a lot of practice with the gun.

Thursday, September 11, 2014

De-Vinyl - Day 2

It just bugs me that I came away with disappointing results

with de-vinyling yesterday. I stopped by Active Electronics on the way home

from work and picked up a few different solder iron tips. I looked for larger chisel

tips and knife edge tips. I also decided to up the temperature of my solder

iron. Playing between 750 and 800deg. I am now seeing much better results. I

have slowed down the pull of the iron across the aluminum to ~1.5sec/inch. If I

pull the vinyl back 180 deg back over itself it leaves a very clean edge. Any

edges that I didn't melt through can be very quickly rectified with a simple

touch of the iron. I'm much more pleased with the results. Although I must say that there is still at

times just a very faint line where the iron has passed over the aluminum. I

would say 5% has just a hint of a line. I resolved that this is acceptable and

to carry on (although I might just double check with Vans Force)

Subscribe to:

Posts (Atom)