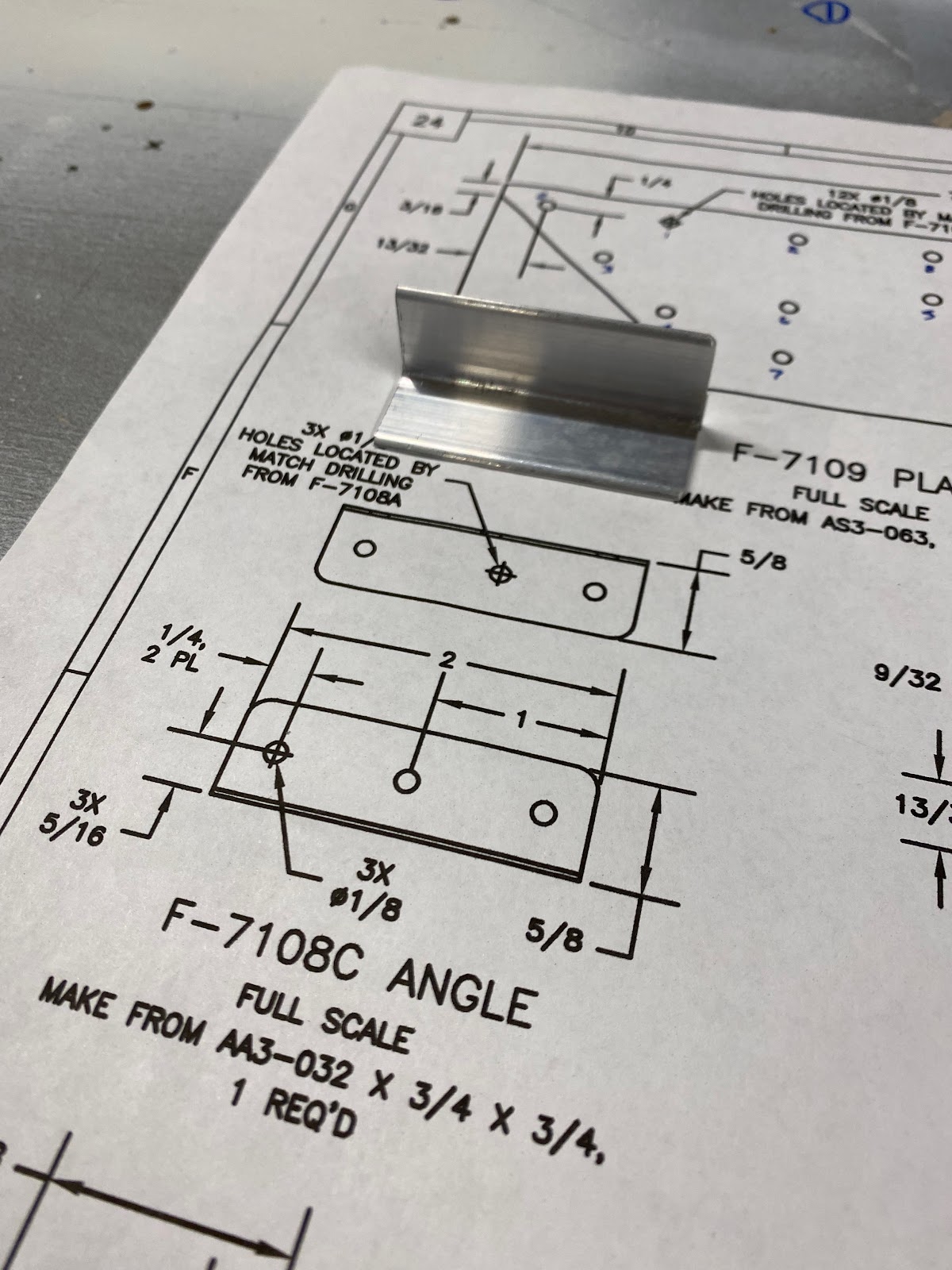

I need to start fabricating and fitting all the various attach angles that are needed for the front deck. The first is the F-7108C angle. I rough cut the angle, trimmed it. Drilled all the required holes in the plans.

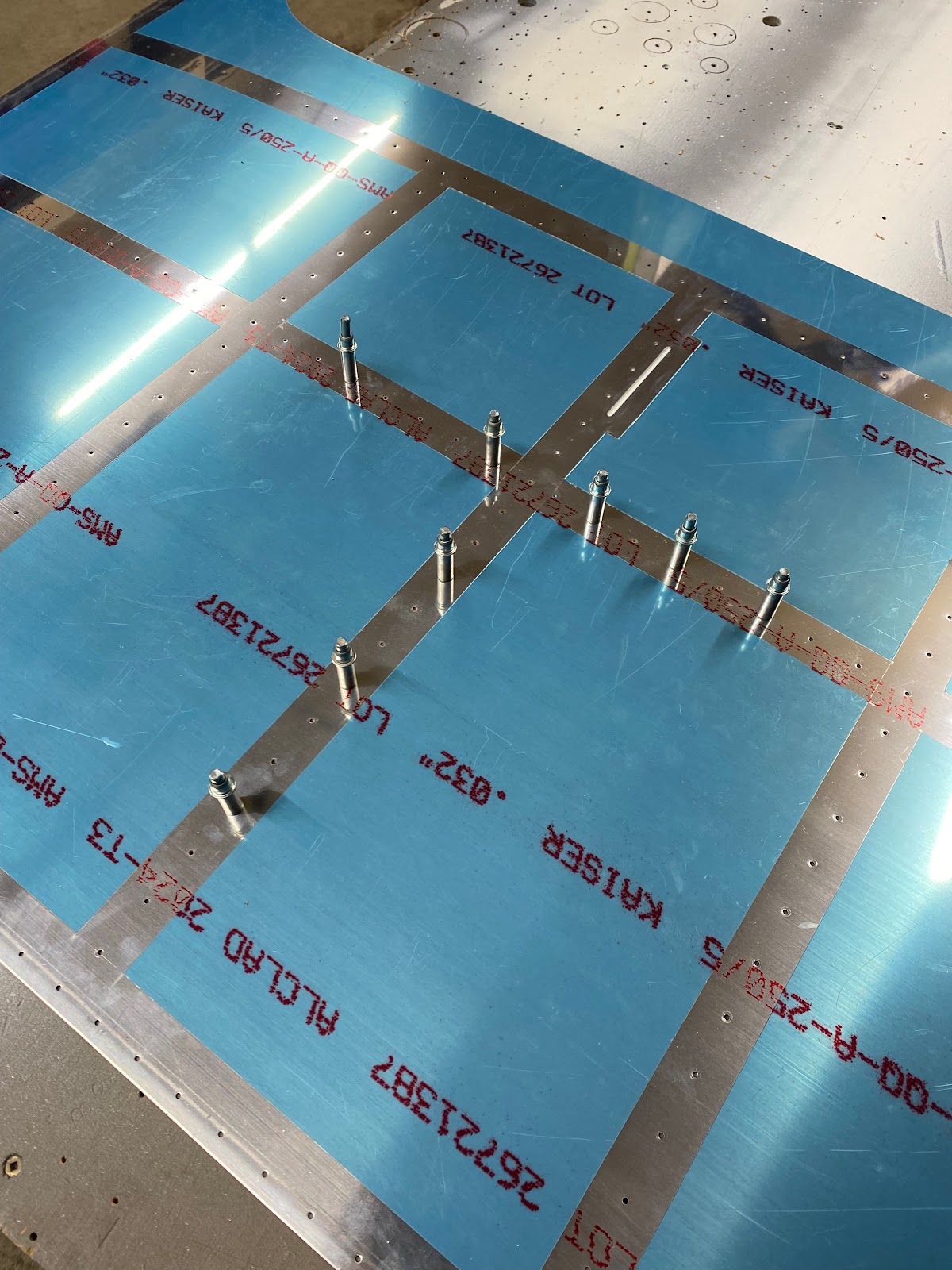

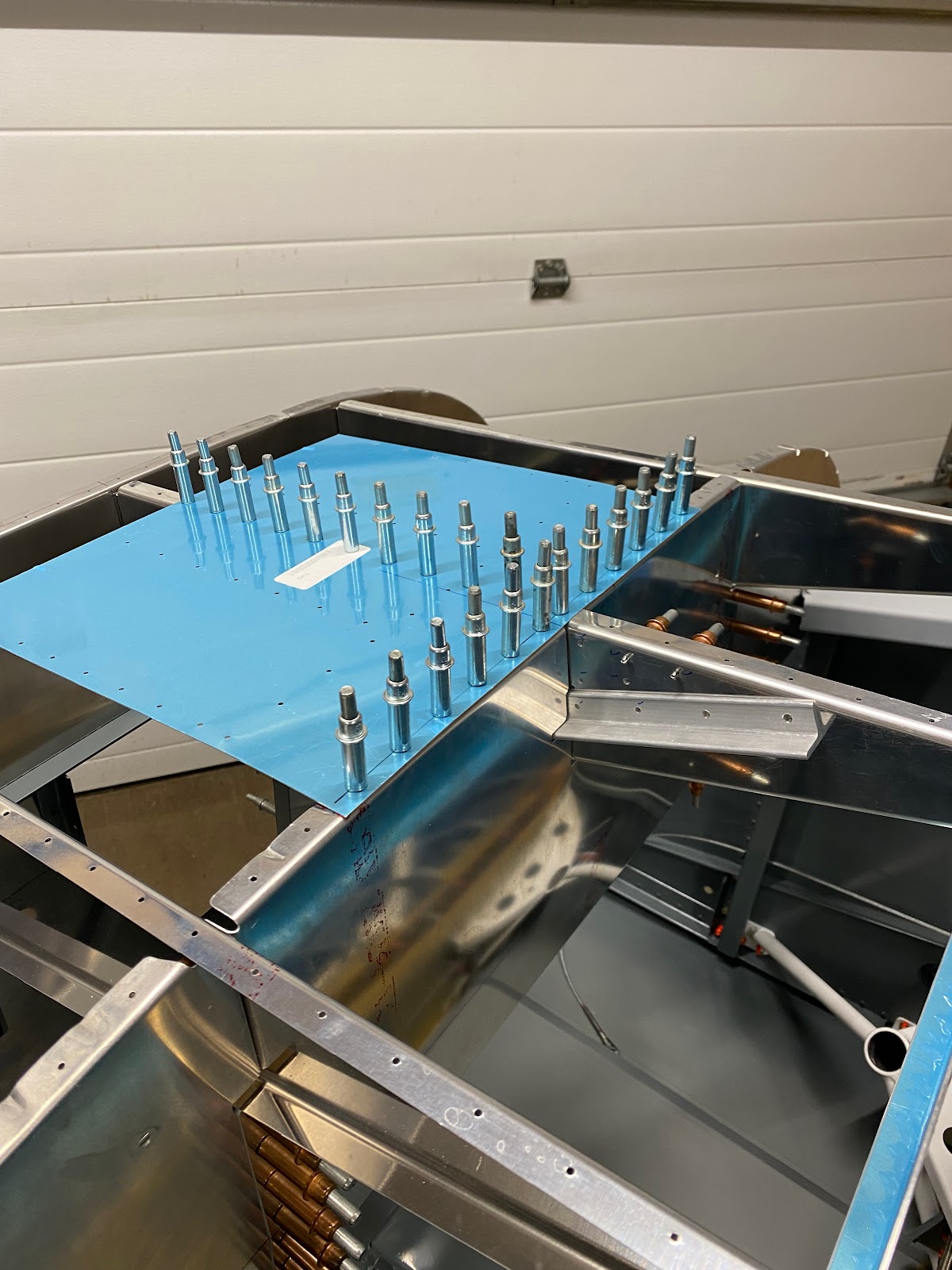

Now, I need to fit it into place to drill the remaining holes. This is the tricky part. I want to ensure the ribs and bulkheads are in the correct place, but fitting the top deck skin make access horrible. To fix this, I used a piece of scrap aluminum that I have from the practice airfoil kit and I match drilled the top skin to that. Now I have a small top skin template to fit to the structure. This will allow me to install the F-7108C angle and drill the remaining holes with confidence everything is fitting correctly.

I upsized the #40 hole in the forward end of the F-7108B angle to #30.

Next I worked on the F-7103C attach angles. These turned out to be more tricky than I would have originally thought. The plans call for the angles to be "Flutted" however the illustration leans more toward this to be a relief opening that is cut into the flange. I opted to go with simply flutting, but soon found the amount of fluting required to get the proper bend is quite extreme.

I managed to fit the attach angles into place and drill them. But at the end of the day, I am not pleased with the flutting as it distorts the angle just a bit too much for my liking. I should have opted to cut reliefs in the angles rather than flutting.

No comments:

Post a Comment