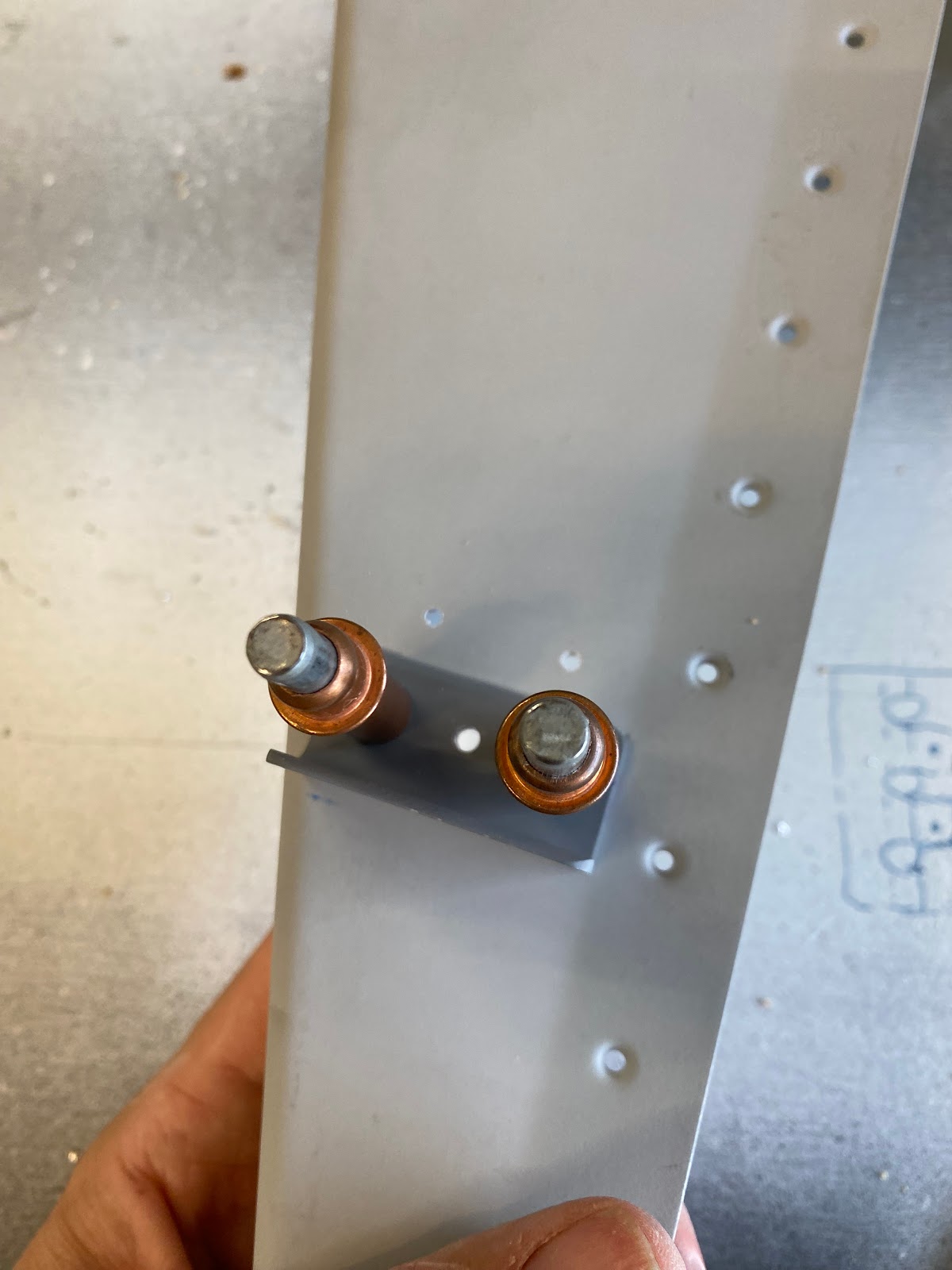

Time to install the WD-641 roll bar permanently. Now that the paint of the front deck is fairly dry and cured, I am ready to work in this area. One thing that I researched this morning was if other builders trimmed the excess steel on the mounting plate. Nobody seems to talk much about it, but from what I can tell in all of the pictures I have, everyone has trimmed this down.

I placed the roll bar on the fuse and drew my reference lines. Yup, I have 2x edge distance so I am good to trim according to my lines. Obviously an angle grinder is a bad idea as the heat wrecks the powder coat and I’m sure will mess with the welds. So I went to town with the hacksaw.

A final finish on the sander station and the trim was a success. I primed the bare cut steel and touched up with white colour matched paint. Did I mention how nice it was to have my 3D printed wrenched for the rear AN4 bolts?!?!

Next, I riveted the F-793 vent brackets to the fuselage

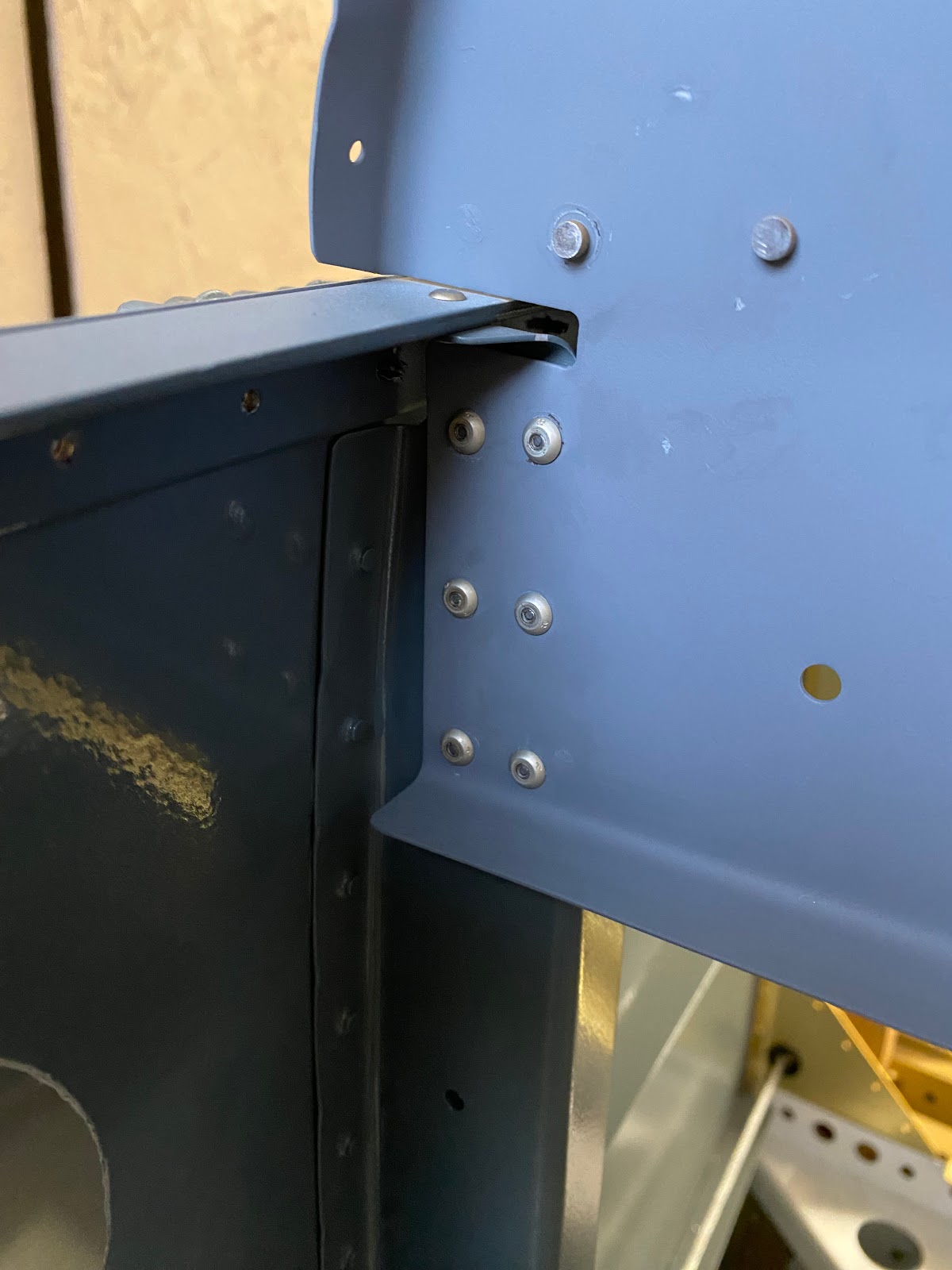

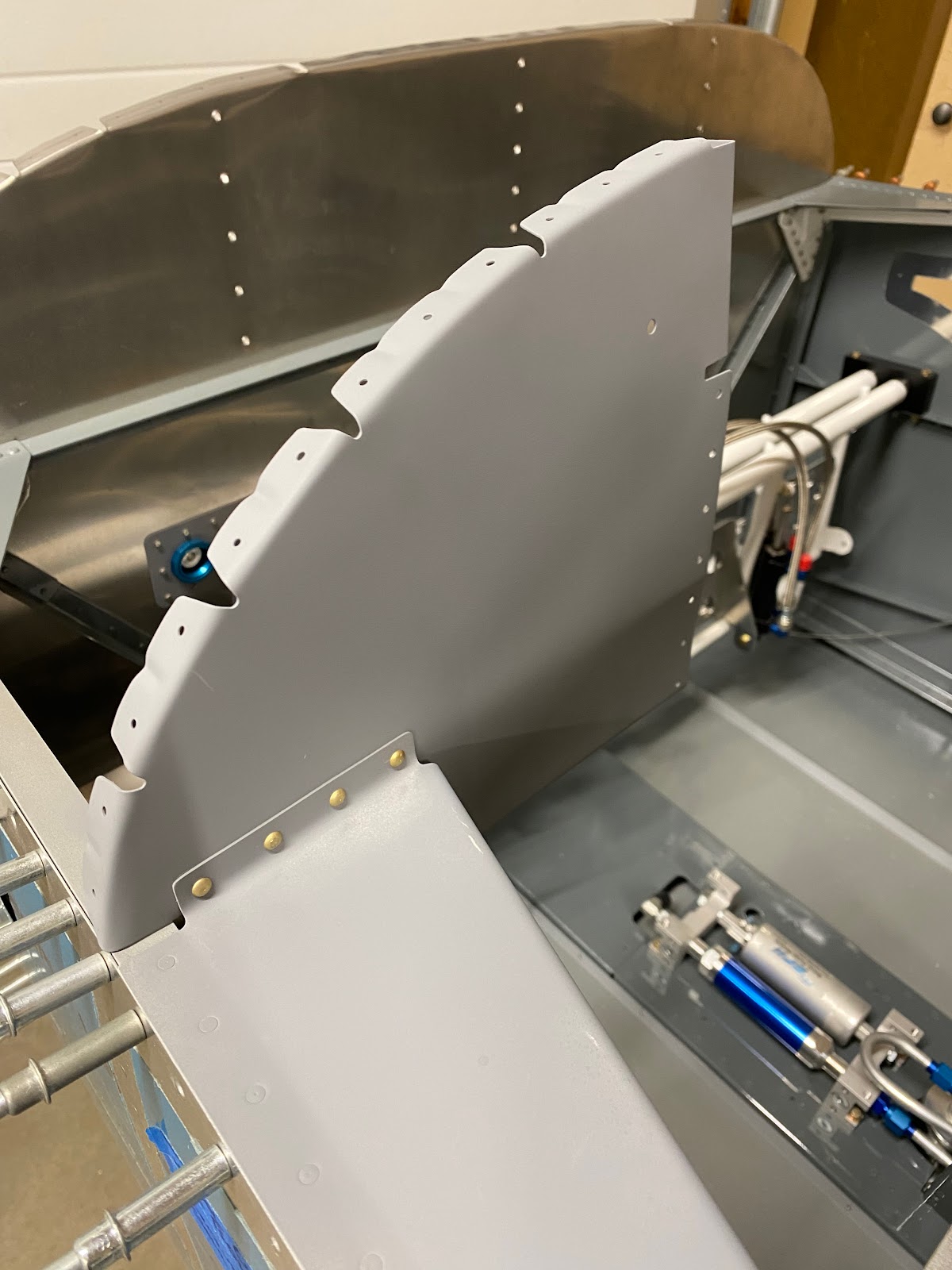

I am now ready to start in on the canopy…… I hope. I've temporarily fit the canopy frame on the fuselage and I can see that I have to make adjustments to the forward bow of the canopy frame to match the lines of the roll bar. You can see how the bow on the canopy frame kicks out on the right side (when looking from the front).