Before I can start prepping the front canopy deck for assembly. I need to put a bit of work into the cabin area and brakes. I did not finish this area off originally as all of the drilling of the front deck results in a bunch of metal filings I didn't want all over the fuel system and brake system.

I removed the center cover to expose the forward brake lines. During the original installation, I didnt get one of the plastic retainers installed as I was short 1 half. So, I took care of it.

Now...The issue I was having with my brake pedestal install last year is that I had an amount of play in the WD-655L/R brake weldments that would (in work case scenerio) allow the two master brake cylinders to rub against each other. To combat this, I need to install a small washer in the F-6116 bearing blocks to limit the amount of potential movement I can get between the two weldments.

Last year I had cut a few 1 1/4" dia x 1/4" thick discs out of HDPE plastic. I just need to trim them down to proper size. Using the 3D printer once again, I made a template/guide so I can trim the white HDPE to a tight press fit in the bearing block. One 1/4" spacer is installed in opposite ends for each F-6116 weldment.

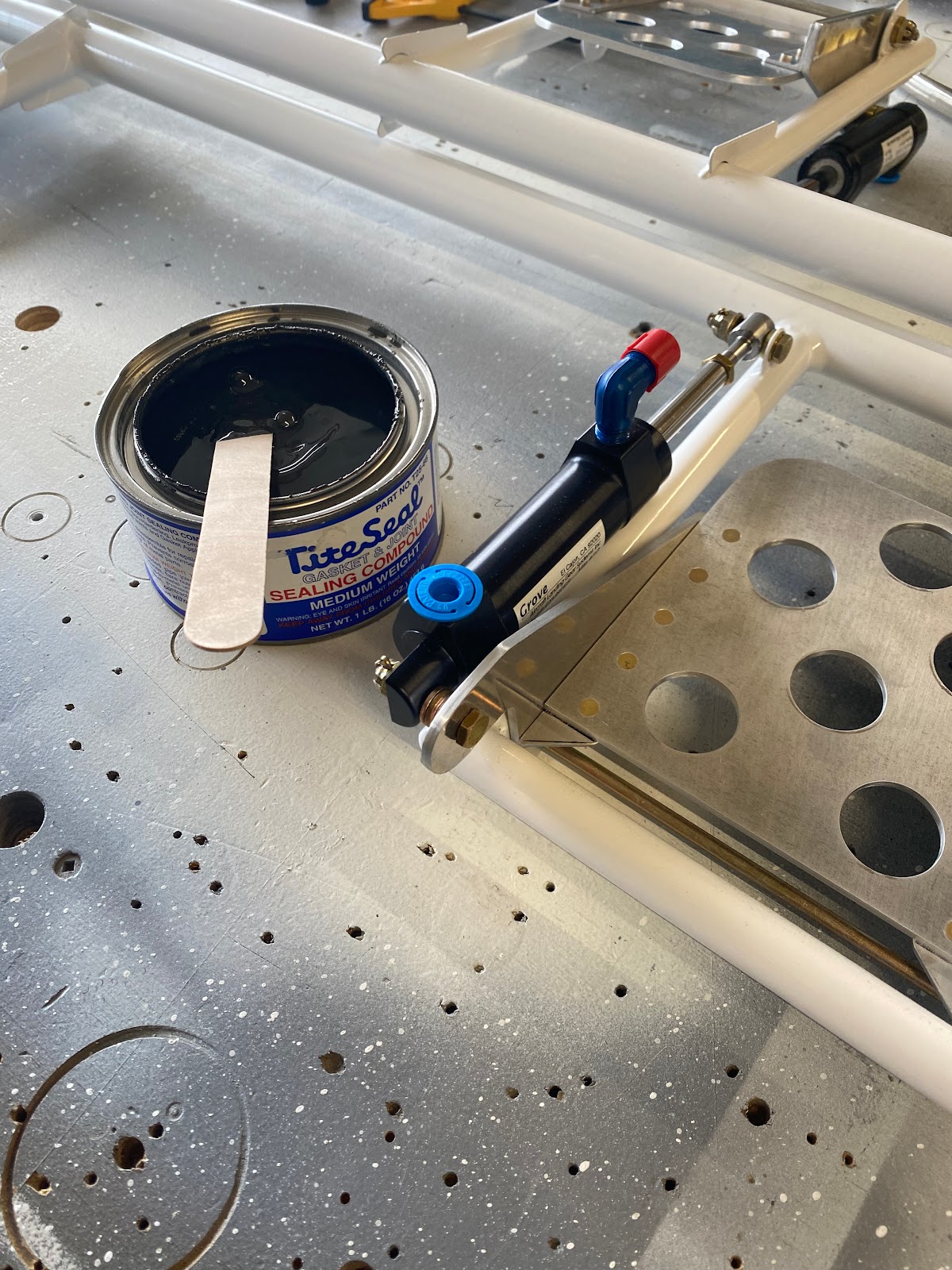

Next, I need to install eight AN fittings in the master cylinders. As per the Van's Instructions, I am using a small amount of tite-seal on the NPT threads to help seal them. Before the brake assembly is installed. I need to finish final installation of the park brake and the park brake lines.

Now I am ready to permanently install the brake pedal assembly. And I can also confirm the 1/4" spacers work perfectly as it prevents any lateral movement in the assembly causing the master cylinders to touch together.

No comments:

Post a Comment