While I’m waiting on the paint to dry on the new platform I built in the garage. I went to work on the center section to clean up a few outstanding items. One of the items I haven’t addressed is countersunk the F-705 bulkhead for the nutplates (for the removable baggage floors).

I countersunk for nutplates and then I masked off the assembly and spot primed the area.

Since I had the primer out, I touched up the skin under the forward F-704 bulkhead/spar.

Next step I need to make sure the aft fuselage is prep’d for the longerons. Reading other build logs. I see that the relief hole for the longerons in the bulkheads need to be enlarged slightly. I have some scrap 3/4x3/4x125 angle so it made adjusting those holes pretty easy.

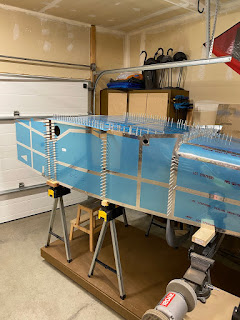

I fitted the longerons to the aft fuselage to check fit.

Like Mike Bullock’s build page. I too had a slight bit too much of Bulkhead F-711 that kept the longerons from sitting flush with the side skin. I will need to trim those down.

I checked the fit at the back and marked the longeron that I purposely left long to be cut right where the rear tab ends. No edge distance issues here!

Using the method Mike Bullock used. I isolated the F-711 bulkhead from the horizontal stabilizer mount with a plastic scrapper and used a small flat file to remove about 1/32” of material. Worked very well.

I sat and looked at it for a while. Looked at other builds. Scratched my head. I think I’ll post this dilemma to the Van’s Facebook group and see what more experienced eyes say.